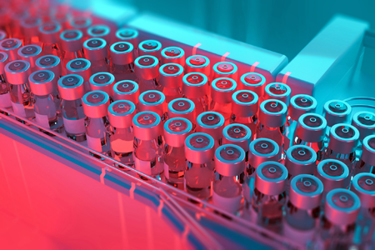

360Q Pharmaceutical Container Inspection System

Higher throughput, more comprehensive inspections and better-quality labels and product.

Pharmaceutical bottle, tube, and container inspection is limited using a single camera or manual inspection, leading to escaping defects that can occur during the labeling process. Furthermore, implementing a complex mechanical device to rotate each piece to create line-scan image of the object can significantly slow down production.

The Verista 360Q pharmaceutical in-line product inspection system has never been so easy and offers less intrusive integration and higher manufacturing throughput than prior methods. It provides a higher degree of labeling integrity versus inspecting labels prior to application, and the ability to inspect 100% of a cylindrical object’s circumference.

By employing a multi-camera solution, Verista 360Q takes independent images, then stitches each image together to “flatten” the product image. This flattened image of your 3D product can then be processed with a variety of tools including:

- Optical Character Verification/Recognition of fixed and variable text

- Barcode inspection (1D and 2D)

- Print quality inspection

- Part gauging (caps, closures, label skew)

- Pattern matching